- English

- Esperanto

- Afrikaans

- Català

- שפה עברית

- Cymraeg

- Galego

- Latviešu

- icelandic

- ייִדיש

- беларускі

- Hrvatski

- Kreyòl ayisyen

- Shqiptar

- Malti

- lugha ya Kiswahili

- አማርኛ

- Bosanski

- Frysk

- ភាសាខ្មែរ

- ქართული

- ગુજરાતી

- Hausa

- Кыргыз тили

- ಕನ್ನಡ

- Corsa

- Kurdî

- മലയാളം

- Maori

- Монгол хэл

- Hmong

- IsiXhosa

- Zulu

- Punjabi

- پښتو

- Chichewa

- Samoa

- Sesotho

- සිංහල

- Gàidhlig

- Cebuano

- Somali

- Тоҷикӣ

- O'zbek

- Hawaiian

- سنڌي

- Shinra

- Հայերեն

- Igbo

- Sundanese

- Lëtzebuergesch

- Malagasy

- Yoruba

- অসমীয়া

- ଓଡିଆ

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

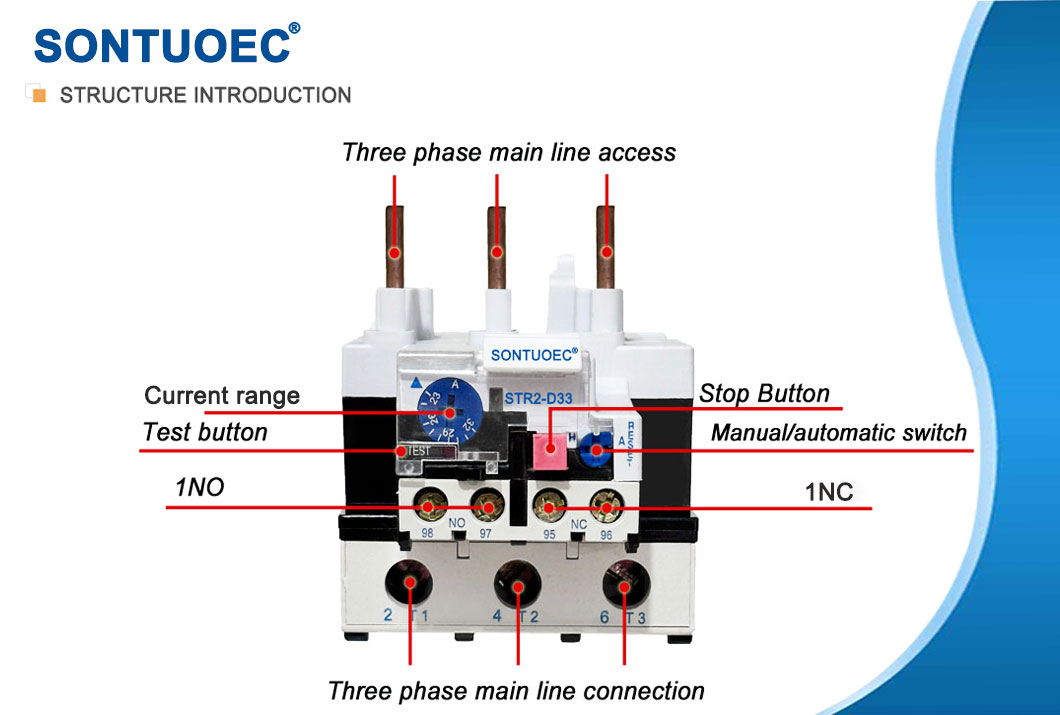

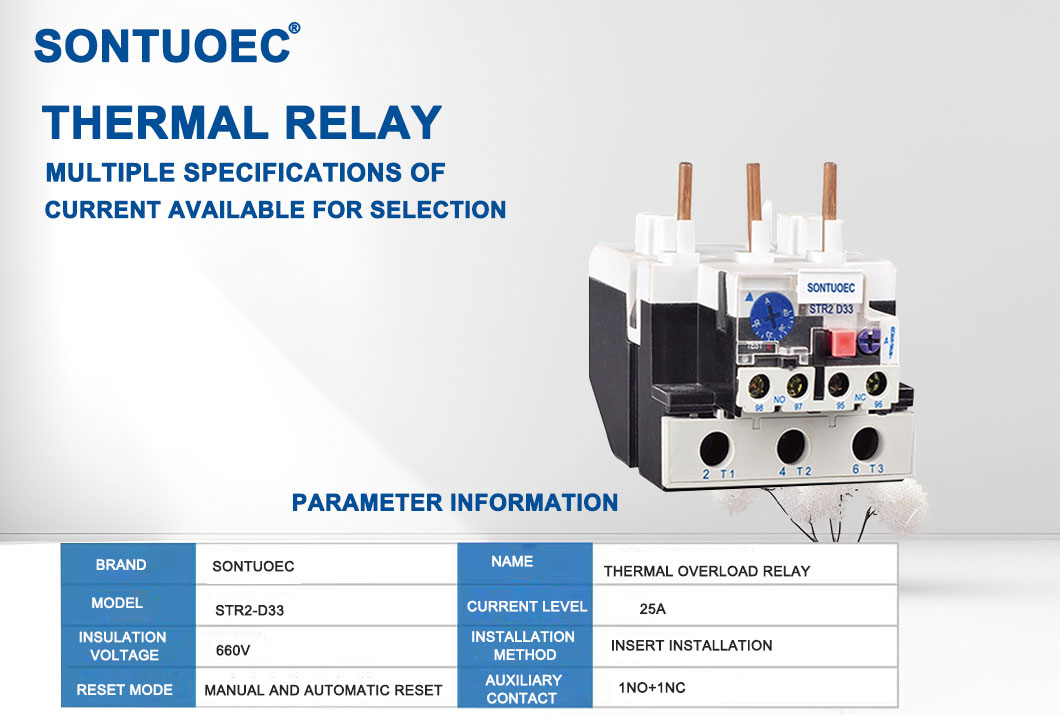

I-STR2-D33 Thermal Overload Sholo edluliselwe

I-STR2-D33 Overral Overload idlulisela umsebenzi ngomgomo wethonya elishisayo likagesi wamanje. Lapho imoto igcwele kakhulu, inyuka yayo yamanje, ebangela into yokushisa ngaphakathi kokudlulisela ngokweqile okushisayo okudluliselwe ukufudumeza. Lokhu kushisa kudluliselwa eBimetal, eyenziwe ngezinsimbi ezimbili ezinama-coefficients ahlukene wokunwebeka okushisayo, ngakho-ke kuyagobhoza lapho kufudunyezwa. Lapho ukugoba kufinyelela iphuzu elithile, kubangela idivaysi yemishini, imvamisa ukuxhumana, okunqamulani ukunikezwa kwamandla emotweni, ngaleyo ndlela kuyivikele emonakalweni.

Thumela Uphenyo

Ukucaciswa:

| Umphumela Ibizo | I-Thermal Overload Slowy | |||

| Isifanekiso | St2-d33 | |||

| Into uqobo lwayo | Ipulasitiki, izingxenye ze-elekthronikhi | |||

| Impamba Thintana | 1no + 1nc | |||

| Impamba Edluliselwe yamanje | 23A-93A | Pls Qaphela okwamanje ukuqhelelana | ||

| Str2-93 | Ibanga lamanje lamanje (a) uhla |

3322 | 23 ~ 26 ~ 32 | Str2-40 ~ 95 |

| 3353 | 17 ~ 25 | |||

| 3355 | 30 ~ 33 ~ 36 ~ 40 | |||

| 3357 | 37 ~ 41 ~ 46 ~ 50 | Str2-50 ~ 95 | ||

| 3359 | 48 ~ 51 ~ 60 ~ 65 | |||

| 3361 | 55 ~ 0 ~ 65 ~ 70 | Str2-62 ~ 95 | ||

| 3363 | I-63 ~ 71 ~ 80 | Str2-80 / str2-95 | ||

| 3365 | 80 ~ 85 ~ 93 | Str2-95 | ||

| Ubuningi bokwenzeka | I-660V | |||

| Ikilasi Lokugibela | 50 / 60hz | |||

| Umbala | Njengoba isithombe esikhonjisiwe | |||

Amapharamitha amahle obukhulu

| Isifanekiso | Kukalwe manje | Cha. | Ukubeka ibanga (a) | Koxhumana naye |

| Str2-25 | 25 | 1301 | I-0.1 ~ 0.12 ~ 0.14 ~ 0.16 | Str2-9 ~ 32 |

| 1302 | 0.16 ~ 0.19 ~ 0.22 ~ 0.25 | |||

| 1303 | 0.25 ~ 0.3 ~ 0.35 ~ 0.4 | |||

| 1304 | 0.4 ~ 0.05 ~ 0.63 | |||

| 1305 | 0.63 ~ 0.8 ~ 0.9 ~ 1 | |||

| 1306 | 1 ~ 1.2 ~ 1.4 ~ 1.6 | |||

| 1307 | 1.6 ~ 1.9 ~ 2.2 ~ 2.5 | Str2-12 ~ 32 | ||

| 1308 | 2.5 ~ 3 ~ 3.5 ~ 4 | |||

| 1309 | 4 ~ 5 ~ 6 | |||

| 1312 | 5.5 ~ 6 ~ 7 ~ 8 | |||

| 1314 | 7 ~ 8 ~ 9 ~ 10 | |||

| 1316 | 9 ~ 11 ~ 13 | |||

| 1321 | 12 ~ 14 ~ 16 ~ 18 | Str2-12 ~ 32 | ||

| 1322 | 17 ~ 21 ~ 25 | Str2-12 ~ 32 | ||

| 1353 | 23 ~ 32 | Str2-25 / 32 (LC1-D25 / 32) | ||

| Str2-36 | 36 | 2353 | 23 ~ 26 ~ 29 ~ 32 | |

| 2353 | 28 ~ 32 ~ 36 | Str2-32 | ||

| 2353 | 30 ~ 40 | |||

| Str2-93 | 93 | 3322 | 23 ~ 26 ~ 32 | Str2-40 ~ 95 |

| 3353 | 17 ~ 25 | |||

| 3355 | 30 ~ 33 ~ 36 ~ 40 | |||

| 3357 | 37 ~ 41 ~ 46 ~ 50 | Str2-50 ~ 95 | ||

| 3359 | 48 ~ 51 ~ 60 ~ 65 | |||

| 3361 | 55 ~ 0 ~ 65 ~ 70 | Str2-62 ~ 95 | ||

| 3363 | I-63 ~ 71 ~ 80 | Str2-80 / str2-95 | ||

| 3365 | 80 ~ 85 ~ 93 | Str2-95 | ||

| Str2-140 | 140 | I-80 ~ 104 | ||

| 95 ~ 120 | ||||

| 110 ~ 140 |

Imisebenzi eyinhloko

Ukuvikelwa okugcwele ngokweqile: Lapho umthwalo wemoto wedlula inani lawo elikalwe, okudluliselwe ngokweqile okushisayo kuzonqamula amandla okuvimbela imoto ekutholeni ngokweqile kanye nomonakalo.

Ukuvikelwa ngokweqile kwe-Overheat: Uma imoto yenyusa ngokweqile ngesizathu esithile (isb.

Ukusebenza Kwonkomba: Ukudluliselwa okuningi okuphezulu kakhulu okuthengiswayo kunomsebenzi oyinkomba, okusayina noma okuguqula isimo lapho imoto igcwele kakhulu noma ishiswe, ukuze opharetha bakwazi ukuthola izindlela ngesikhathi.

Uchungechunge lwe-Auto Relay str2-D lokudluliselwa ngokweqile okushisayo lungasetshenziswa esifundweni se-50/60 HZ, ukufakwa kwezimali okulinganiselwe ku-acray acray, kudluliselwa kwemoto ye-ST1, kungcono kakhulu ukudluliselwa kwe-acrate, kudluliswa okudluliselwe phambili kwe-actifing, kungcono kakhulu okudluliswa kwe-IEC 60947-1.

Izimo Zokusebenza

Ukudluliselwa ngokweqile okushisayo kusetshenziswa kabanzi ezindaweni ezahlukahlukene zezimboni nezentengiso, ikakhulukazi emishini edinga ukushayela kukagesi. Isibonelo, zisetshenziswa kumaphampu, ama-compressors, abalandeli, abathunisi, kanye neminye iminye imishini yemishini yokuqinisekisa ukuthi imishini enjalo ingavalwa ngokuphepha emcimbini wokulayisha ngokweqile noma ngesimo sokushisa ngokweqile.

Ukukhetha nokufakwa

Lapho ukhetha i-Thermal Overload ephelele, izici ezinjengesilinganiso samandla e-motor, indawo yokusebenza, kanye nezimpawu zokulayisha kudingeka zibhekwe. Kuyadingeka futhi ukuqinisekisa ukuthi i-therated yamanje yokudluliswa okugcwele okugcwele okulayishwa okulinganiselwe kufana ne-motor yemoto nokuthi inesici esifanele ngokweqile kanye nezimpawu zokuvikela ngokweqile.

Lapho ufaka i-Thermal Overload edluliselwe ngaphezulu, udinga ukulandela imihlahlandlela yomenzi futhi uqinisekise ukuthi ixhunywe kahle kumandla okusebenza kanye nokulawula. Ngaphezu kwalokho, ukudluliselwa okugcwele okushisayo okuphezulu kudinga ukuhlolwa futhi kugcinwe njalo ukuqinisekisa ukusebenza kahle nokuphila kwenkonzo ende.